Industrial shredders are automated or semi-automated machines that process and destroy materials in advance of disposal or recycling, specifically by shredding them. They also contribute to space saving via waste size reduction. Shredder machines are popular in many industries, including milling, healthcare, recycling, paper production, waste removal and parks and recreation. Read More…

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions.

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred!

More Industrial Shredder Manufacturers

The shredding industry provides a vital service to a wide variety of customers, including recycling plants, individual recyclers and schools, medical practices, law firms and government agencies, which shred hard drives and paper documents to protect privacy.

All sorts of products can be recycled and treated for reuse. Old cars, scrap metal, old tires, car bumpers, tree branches, plastic bottles, newspapers and other non-classified paper, steel drums, tubing and cable are all examples of materials that can be recycled, shredded or granulated and turned into something new.

The first specialized paper waste shredder, patented as the Waste Paper Receptacle, was created in 1908 by Abbot Augustus Low. However, though the American inventor patented his invention, he never put it into production, and industrial shredding was not revisited until the 1930s.

The next major shredding invention had more sensational roots. It was invented in 1935 by a German engineer, Adolf Ehinger, who supposedly invented it to his shred anti-Nazi propaganda, so that the regime had no reason to question or indict him. Either way, Ehinger’s shredder was a success. Sometime later, he switched out the hand crank for an electric motor, then marketed his machine to, coincidentally, the government. Ehinger went on to form his own company, EBA Maschinenfabrik. In 1959, this company produced the first cross-cut paper shredder.

Shredders gained popularity during the Cold War, when governmental offices obsessively destroyed sensitive and confidential papers. Use of shredders outside of governmental offices was not common until near the end of the Cold War, in the mid-1980s. This change initially took place for a few reasons. First, in 1988, the Supreme Court ruled that the Fourth Amendment does not formally forbid the warrantless search and seizure of garbage left for collection on the curb (California v. Greenwood). This caused anxiety about the infringement of privacy and pushed citizens to begin shredding their personal documents. In addition, people turned to shredding as an alternative to burning their documents as new laws prohibiting or limiting burning took effect.

One of the greatest catalysts to the rise in popularity of industrial shredding equipment was the advent of the digital age. Since the ‘90s, companies, banks, medical offices and the like have found it necessary to do more to protect personal information. To keep customers, patients, companies and governmental offices safe, many have turned to more heavy-duty shredders, such as hard drive shredders.

In addition, laws regarding recycling, and a general interest in caring for the environment, has led to the development of industrial shredders designed as recycle equipment. These shredders process recyclable and reusable waste materials, like cardboard, plastic and scrap metal. They are incredibly diverse in shape and size. The world’s largest scrap metal shredders, designed in Portland, Oregon, resides today at the mouth of the River Usk in Newport, Wales. Built in 1980, this shredder can shred up to 450 cars an hour.

Today, industrial shredders are an important part of many thriving businesses and institutions. They help keep information safe, cut down on costs, save energy, conserve resources and generally support sustainability.

How It Works

The workings of industrial shredders are pretty straightforward. Operators hand-load or machine-feed the waste material into the loading area (usually a hopper or conveyor), and let it be reduced through a cutting and/or compacting mechanism. Once shredded or ground, operators can package the material for transportation to its next destination. Sometimes, the shredders work in conjunction with balers, which compact and then bind the material into rectangular or cylindrical bundles.

Note: Some shredders are hand-fed, but aside from small, home shredders, this is now a rarity due to safety concerns.

Types

Manufacturers produce a myriad of industrial shredders to shred and crush different materials. They also fabricate shredders to destroy specific products, like tires or hard drives. Learn more about these shredders by reading the descriptions below.

Metal Shredders

Manufacturers produce metal shredders in order to waste metal or scrap metal for recycling or reuse. They reduce metal of all shapes and sizes into something manageable. They are a common sight at scrap yards, where they can reduce energy consumption and its associated costs by as much as 75%.

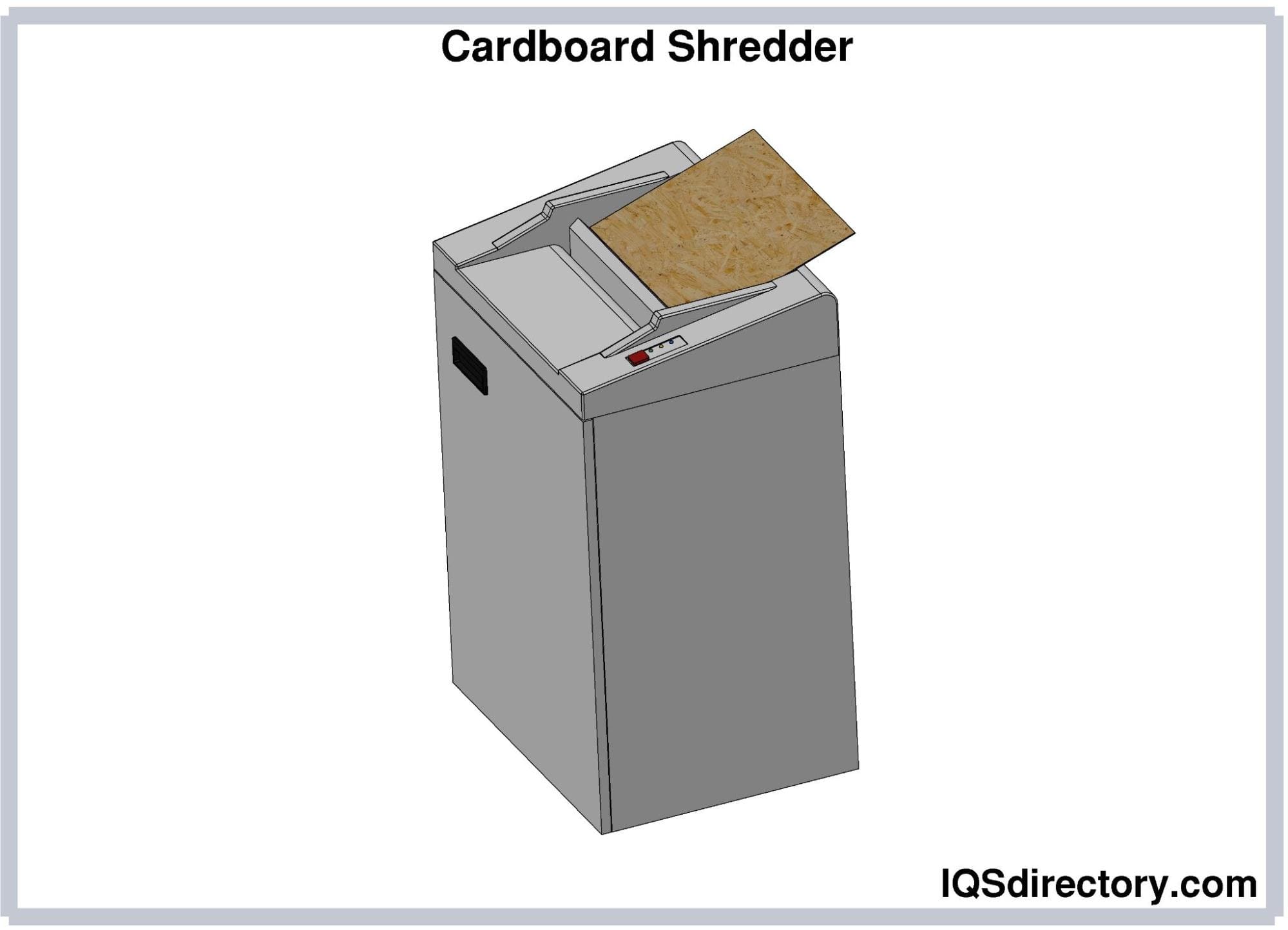

Cardboard Shredders

Cardboard shredders, also known as cardboard cutters, are used to transform cardboard structures into a more transportable bulk form. They are useful to customers in a number of industries, including: food service, recycling, paper and pulp, office and manufacturing. Cardboard shredders are advantageous because they cut down on significant amounts of waste. Some companies may opt to purchase a cardboard shredder of their own, while others will hire a third party to do the shredding for them.

Industrial Grinders

Industrial grinders feature either a set of rollers or a high-pressure hopper. With them, they slowly weaken and compress materials until they crush into bits or powderize. Industrial grinders are popular for use in: recycling, landscaping, construction, furniture and cabinetry and milling. There, they process hard materials like clay, shale, wood and plastic.

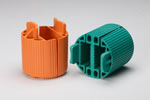

Plastic Shredders

Plastic shredders convert plastic products into plastic granules. Granulated plastic can be melted down and recycled into new parts and products. Plastic shredders are highly customizable and may feature add-ons like conveyor belts, forklift-fed hoppers or hand-fed hoppers. In addition, they may be automatic or manual, and vertical or horizontal. Plastic shredders can process plastic products of all shapes and sizes. Examples include: car parts, small bags, pipes, siding, bales, bottles, drums, bottles and more.

Granulators

As their name suggests, granulates are designed to form materials in particles or grains. To do so, they use high-speed open or closed rotors. Granulators can reduce materials down to much smaller granules than can grinders and shredders. Grains processed in granulates usually range in size between .2 and 4 mm.

Granulators may operate using dry granulation or wet granulation. During dry granulation, the granulator uses a compactor and no liquid to grind the material. Dry granulation is best for sensitive materials and light materials like rubber. During wet granulation, manufacturers pair a granulation liquid with a powder bed. The granulator mixes them using air, screws or an impeller, causing agitation, which in turn creates wet granules.

Hard Drive Shredders

Hard drive shredders are used to shred computer hard drives. Customers take this extra step when the data stored on the drive is too sensitive to risk recovery. Hard drive shredders destroy them by tearing into them with rough, sharp and crushing rotary blades or hook cutters. Hard drive shredders are popular with customers like the US military. They’re also useful to large companies that do not want to dispose of their hard drives in landfills, where they may cause pollution.

Chipper Shredders

Chipper shredders turn material into small chips, like rubber chips or wood chips. Chipper shredders are especially useful in recycling and reprocessing materials because they make such uniform pieces. Chipper shredders can be permanent installations or small and portable.

Tire Shredders

Tire shredders are used to create rubber chips or crumbs from rubber tires. Rubber crumb is used for indoor playing fields, new tires and asphalt.

Wood Chippers

Wood chippers, sometimes called wood shredders, exist to create wood chips. Examples of wood chip applications include: walkways, lawns, gardens and playgrounds. In addition to being gathered from trees, wood chip wood can come from wood waste such as old blocks, pallets and crates.

To further assist in their customers’ various applications, suppliers offer several shredder services, such as off-site shredding, remote shredding and mobile shredding.

Off-Site Shredding

Off-site shredding is a common service, during which gathered materials are transported to a recycling facility. Off-site shredding is used heavily by recycling plants to process wood and other organic materials, non-working vehicles, plastics, cardboard, tires and scrap metal.

Remote Shredding

Similarly, in remote shredding, documents to be shredded off-site are picked up by a driver and driven to a recycling plant the same day. Materials shred using remote shredding include branches, crates, cardboard boxes and other recyclable materials gathered in the home.

Mobile Shredding

Mobile shredding is a service utilized by government agencies, medical practices and other businesses that are restricted by privacy laws like the Health Insurance Portability and Accountability Act. Laws like this require that they have a witness present for the shredding of documents. So, mobile shredders come to them on modified trucks that contain shredders that can shred up to 8,000 pounds of paper within an hour on the spot.

Equipment Components

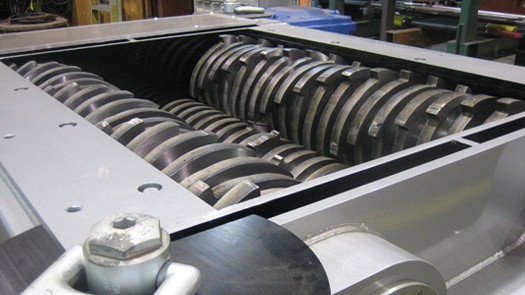

Industrial shredders consist of: feed shafts, a feed area into which materials enter, slicing blades or crushing gears, and a chute that transports materials into a conveyor for further handling, or a receptacle for disposal.

Many shredders also have screens to catch shredded material that is too large for the finished product. Not to be wasted, the caught material is sent back through the shredder as many times as it takes to get it down to size.

Design and Customization

When designing an industrial shredder, manufacturers take a number of factors into account, including: the material to be shred, the volume of material to be shred, the environment in which the shredder will work (on a farm, in an office, indoors, outdoors, etc.), the amount of space allotted for the machine, the frequency with which the shredder will be used and client budget.

To meet your custom requirements, shredder manufacturers can produce your shredder equipment with a wide variety of configurations. Depending on your application, shredders may be small, hand-fed and located in the home or office, or they may occupy commercial shredding plants, shredding thousands of pounds of material by the hour.

Safety and Compliance Standards

To ensure worker safety, we recommend that employers train their workers in responsible shredder loading and unloading. The best information on safety practices and safe working environments comes from OSHA (Occupational Safety and Health Administration). As a governmental agency, OSHA is possibly the most important work safety administration in the country. Make sure that your manufacturer offers OSHA-certified equipment.

In addition, many industries, like scrap metal recycling, defer to OSHA regulations. So, make sure you know what standards and regulations your application/industry/location require your equipment and your processes to meet.

Things to Consider

To make sure you get the most appropriate and efficient shredding equipment for your application, we recommend you work with an experienced and proven industrial shredder supplier. You want to work with an expert in both construction and customer service because they can offer the best advice, services and products. Find a manufacturer that suits your needs by checking out the various industrial shredder company profiles we have dispersed throughout this page.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services