A pallet is a flat transport structure that stably supports goods as they are being lifted by a forklift, pallet jack, front loader, work saver or crane. Read More…

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions.

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred!

More Pallet Shredder Manufacturers

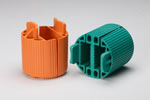

Pallets are most commonly made of wood, but may also be made of plastic, metal, paper or recycled materials. Pallet shredders are designed to shred and reduce pallets and products and materials similar to them, such as crates, medium-sized wood scraps and corrugated sheets and forms.

Pallet shredders are made with a variety of designs and power sources, but are generally powered by a strong engine and feature robust, sharp blades for shredding. Variable specifications include: drive (electric or otherwise), number of motors, horsepower, voltage, blade thickness, number of blades, blade diameter, hex size, distance between shafts, cutting chamber, discharge height, hopper height and stand opening length and width.

To customize your shredder, manufacturers offer a myriad of optional features, such as PLC interfacing, custom stands and hoppers, feed and discharge conveyors, cart tippers, airveying discharge, explosion-proof motors, pneumatic or hydraulic rams and vibrating, magnetic or rotary separation.

Pallet shredders are useful for both home and industrial applications. One example is landscape cleaning, which can be a project on a private residence or on a building site. In this instance, an operator uses the pallet shredder to shred wood that cannot be salvaged for other projects as-is. The pulverized wood chips may then be disposed of or sold for use in the creation of pressed wood products like pressboard.

This practice is comparatively Earth-friendly, preventing wood/material burning and encouraging recycling. Pallet shredders are routinely used to repurpose old and used materials and structures. They are a great choice for preparing materials for uses like mulching or insulating. This material may mulch flowerbeds, insulate homes, provide definition for walking paths and more.

Other typical applications of pallet shredders include: MSW reduction, landfill densification, landfill mining reclamation, disaster clean-up, fuel feedstock, composting, rendering and total product destruction.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services