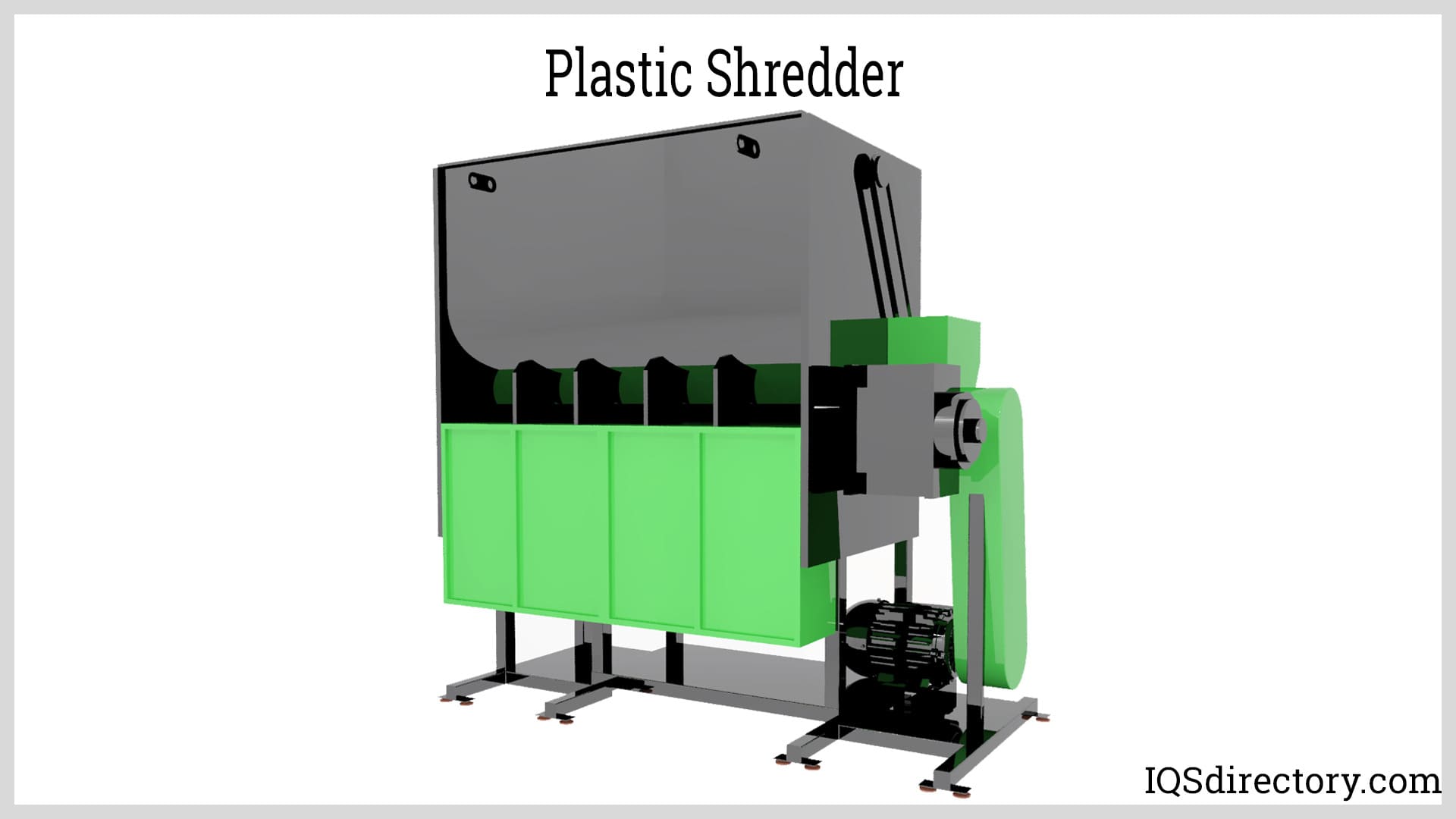

Plastic shredders are essential in plastic recycling factories and manufacturing operations. In addition to processing plastics used as raw materials for various items such as storage containers, toys, packaging bags, and consumer electronics, it provides several other advantages. For example, industrial plastic shredders aid in size reduction and the recovery of waste plastic. Therefore, shredders are essential to efficient and cost-effective recycling and waste management operations. Plastic shredders are designed to shred a wide range of polymers; therefore, they range in speed from low to moderate to high torque and come in various specifications and blade diameters. Read More…

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions.

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred!

More Plastic Shredder Manufacturers

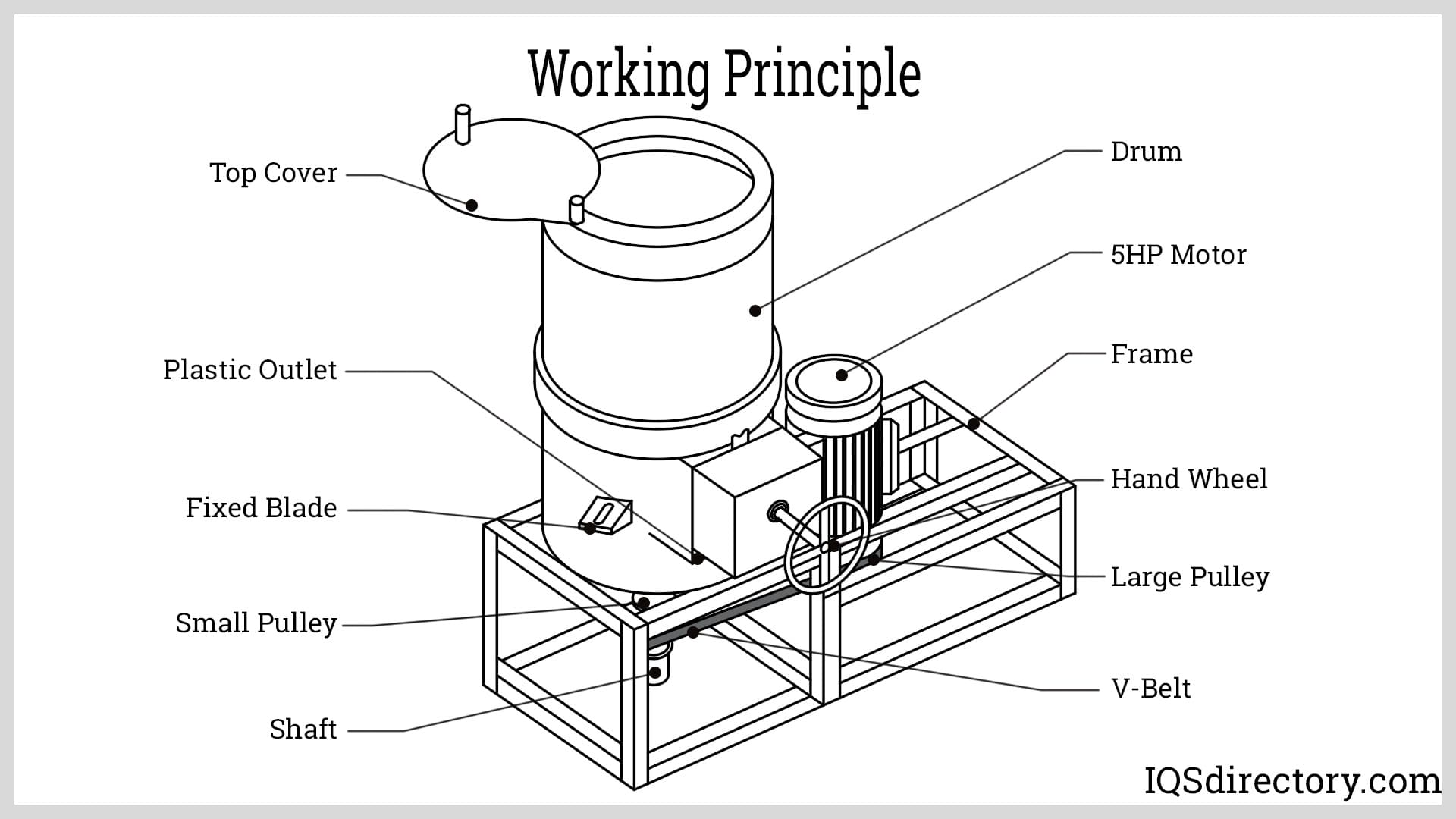

Plastic Shredder Operational Principle

Power is initially given to the motor via a power source. The motor has two switches: forward and reverse. The gearbox output shaft is linked to the shredder shaft. The power from the motor is delivered to the shredder shaft via the gearbox. For the opposing rotation of another shaft, a gearing system is given. The plastic to be shredded is now fed via the top hopper. The claws on the rotor drag the material into the crushing cavity during the operation. When the plastic comes into contact with the blades, it is crushed, and shear stressed, causing it to be chopped into finer pieces. The blades are staggered and impeded for the material to be cut and broken simultaneously in horizontal and vertical directions. After fracturing, the material is intercepted and peeled off by the partition before being ejected downward. Finally, the shredded pieces are collected in a collecting basket after exiting the shredding chamber.

Plastic shredder machines are essentially crushing machines that are used for precision shredding. They are typically used to reduce the size of unprocessed raw materials or leftovers. Shredding plastic waste and using it as raw material to melt and pellet it to make new plastic bottles, tires, or trash cans is a common example. Shredders are commonly used in industrial plastic to crush waste large-caliber PE plastic pipes, bundles of plastic films, big stacks of plastic sheets, and head materials.

Plastic Shredder Categories

Hammer Mills: A rotary drum with swiveling hammers shatters or pulverizes materials.

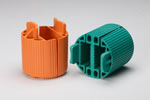

Granulators: Granulators are used to recycle plastic from manufacturing operations. Granulators also have thermoforming devices for producing easy-to-handle scrap material.

Chippers: Chippers use high-speed rotary knives to convert the material to flakes and chips.

Grinders: Grinders pulverize materials and produce granular products by combining the forces of abrasion and compression.

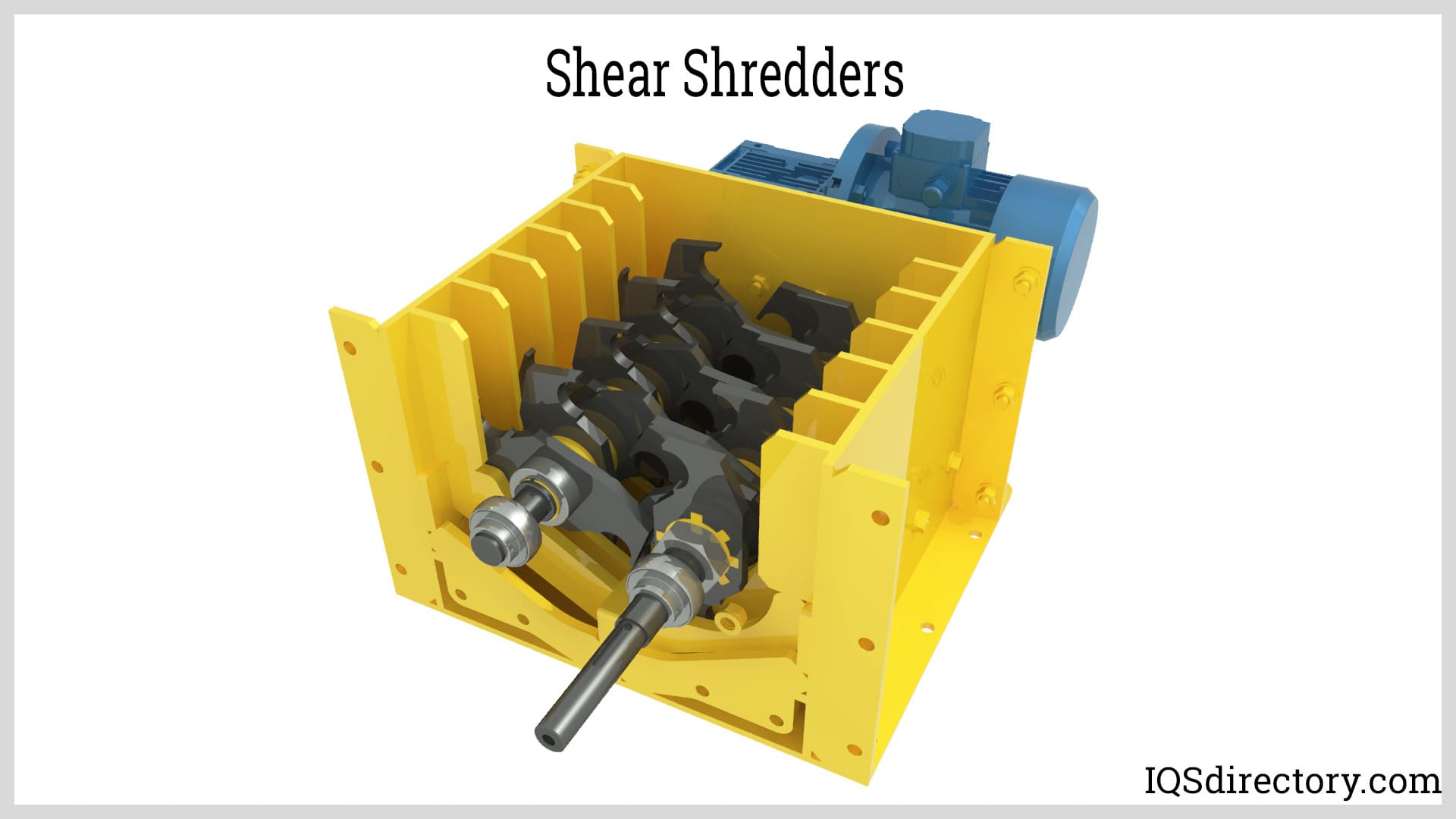

Shear Shredders: Available in various configurations, these shredders use rotary cutters and guillotine-style knives to cut materials based on industrial requirements.

All-Purpose Shredders: All-purpose shredders are used for various tasks. All-purpose shredders are huge, low-speed machines with high torque shafts widely utilized in recycling and demolition operations.

Plastic Shredder’s Role in Commercial Industries

Plastic shredders, regardless of size or shape, are an efficient and practical solution for converting scrap materials into valuable resources. Shredders are highly beneficial when working with plastics, vinyl materials, and PVC pipes. Plastic in any undesired state can be converted into a manageable and usable material that can be utilized to manufacture various items. To ensure efficient and high-quality plastic shredding, one must select the proper machine based on its usability and the required performance.

Advantages of a Plastic Shredder

Some useful features of plastic trash shredders are as follows: these sorts of shredding machines help to recover plastic waste and reduce size. To ensure safe operation, these types of equipment are typically equipped with overload prevention and phase failure protection devices. Numerous companies offer plastic shredder machinery appropriate for shredding various plastic objects while providing efficient and speedy performance.

Most plastic shredder manufacturers provide plastic shredder machinery in customizable sizes to meet the needs of their customers. These devices are made from high-quality raw materials to assure longevity and good performance. In addition, these devices provide various cutting and knife technologies; these blades also come in various sizes and forms to convert plastic components or scrap materials into products that can be reused in various manufacturing procedures. The plastic shredder machinery incorporates multiple cutting chambers and a powerful motor to achieve the finest results. Apart from plastics, other materials such as glass and steel can also be resized with the help of these machines. Plastic trash shredders are also environmentally friendly in addition to these applications.

Considerations When Choosing a Plastic Shredder

Different industrial shredders for plastic shredding are available depending on the size and type of plastic debris to be treated. A plastic shredder's internal mechanism normally travels in lateral, vertical, or rotating directions, and the speed changes depending on the material. Therefore, one must understand how each plastic shredder operates and which one will work best for their specific needs.

Choosing the Correct Plastic Shredder Supplier

To make sure you have the most productive outcome when purchasing plastic shredders from a plastic shredder supplier, it is important to compare at least 4 to 5 suppliers using our list of plastic shredder companies. Each plastic shredder supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic shredder business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple companies with the same message.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services