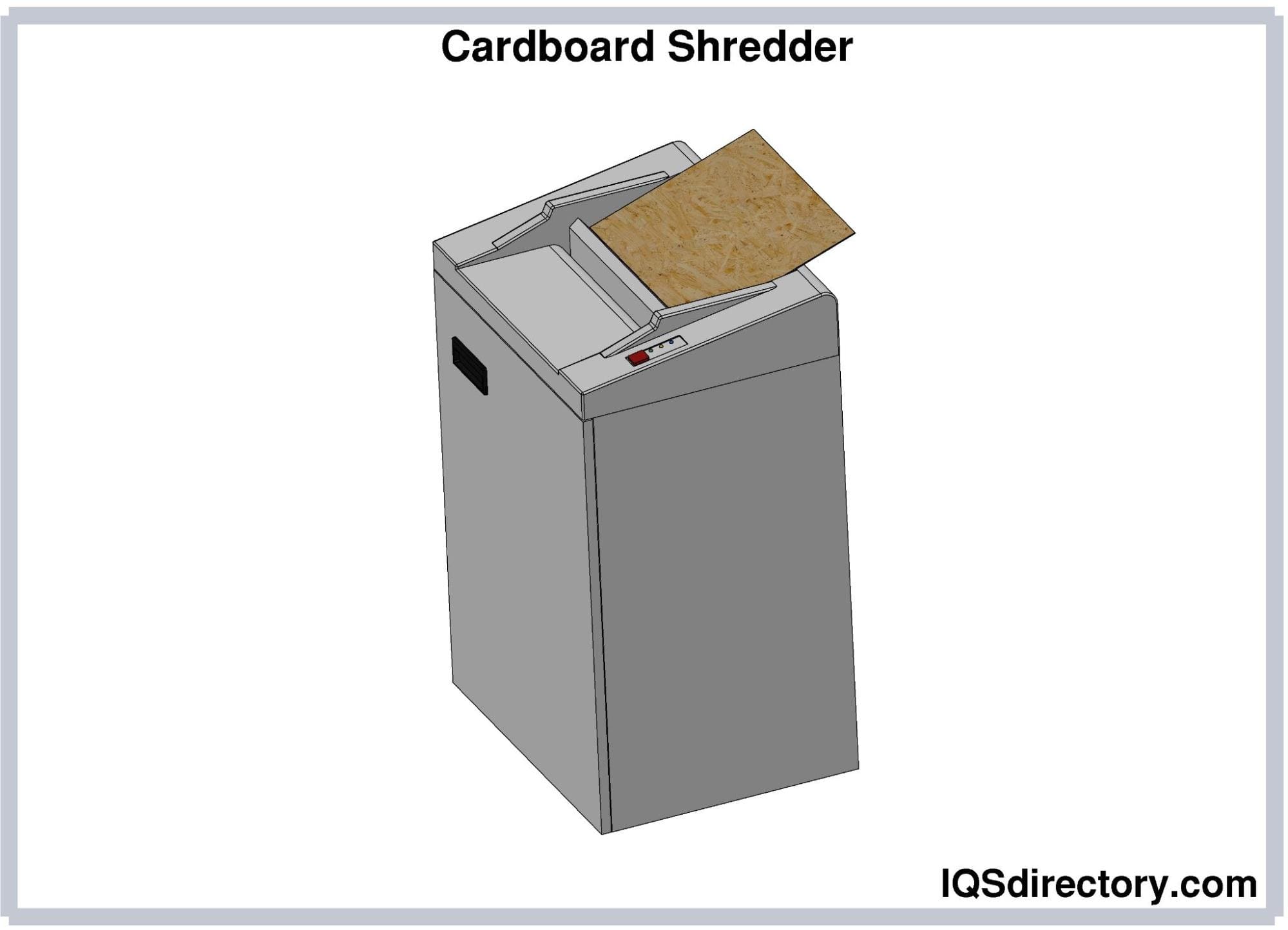

Shredders are commonly used to process materials into different sizes for separation or to reduce the recycling cost of transport. However, the primary use of shredders is to upgrade material by shredding metals, plastics, aluminums, metal, pallets and waste materials like municipal solid waste, nuclear waste, medical waste or hazardous waste including garbage. Read More…

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications.

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions.

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred!

More Used Shredder Manufacturers

To economically secure one of these versatile machines without having to rent, consider used shredders. Used shredders are a great option, not just because they are inherently more economical than new shredders, but also because they are competitively priced and sustainable. These shredders could have as little as a few hours of use, but because they are used, the cost to you is much lower.

Engineers working for used shredder retailers can often recondition and reconstruct shredders for your custom needs. By building your machine from refurbished parts, you get a shredder that is unique to you. Or, if you prefer, you can purchase a shredder as is! No muss, no fuss, just a job well done. Also, since distributors of used shredders frequently offer an inventory of options from multiple manufacturers, by shopping used, your possibilities quickly multiply as your costs go down.

Distributors of used shredders can do a lot for your application. They can recondition shredders to meet various industry and national standard requirements for quality, performance and medical clearing. They will also generally offer many value added services, such as pre-purchase consultation, support during and after your shredder is readied and sent to you, offering tweaks, paint jobs, repairs and equipment performance tests.

For many applications a new shredder may be the best option, but for those applications that may not need the latest shredding equipment, a used shredder will often satisfy your requirements.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services